Thermally stable adenoviral formulations through spray drying

Tech ID

16-020

Inventors

M. Thompson

Z. Xing

D. LeClair

E. Cranston

Patent Status

US Patent 10,752,876

Stage of Research

Proof-of-principle has been performed

Contact

Glen Crossley

Associate Director

Business Development and Intellectual Property

Abstract

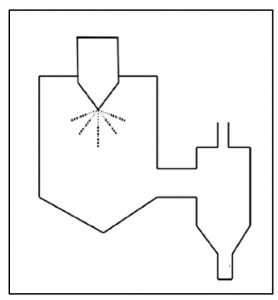

Adenovirus-based gene transfer vectors are being increasingly developed as promising vaccine platforms against both old and newly emerging infections1-3. However, the real-world application of adenoviral vectors, particularly in developing countries, is challenging due to their instability when stored or transported at even mild temperatures. The cold chain requirements for maintaining stability increase the vaccine’s cost and create logistical challenges for distribution and storage. A promising approach capable of increasing thermal stability is through vitrification with excipient matrices, preferably by spray drying due to scalability and favorable economics. Simple excipient formulations appear poorly suited to stabilizing the viral vector and more complex formulations yielding a well-stabilized spray dried form had yet to be developed until the present invention.

A robust method for preparing a thermally stable adenovirus formulation has been developed through the immobilization of adenoviral vectors in a multi-component non-cytotoxic carbohydrate matrix by spray drying. This work extends the possible applications of adenovirus-based vectors as thermally stable vaccines.

Applications

- Production of thermally stable adenovirus vaccines

Advantages

- Economically feasible storage options for adenovirus-based vaccines. Present commercial technology relies on refrigeration for proper storage and transportation

- Simpler spray dried composition than other related developments for better powder yield and lower loss of adenoviral vector activity through the spray drying process

References

- Zhu, F. et al., Lancet 2015, 6736 (15), 1-8

- Majhen, D. et al., Hum. Gene Ther 2014, 25 (4), 301-317

- Lasaro, M. et al., Mol. Ther 2009, 17 (8), 1333-1339